Valgus intertrochanteric osteotomy is a well-recognized treatment for nonunion neck fractures. It is associated with a high rate of union and low complication rates, but requires careful preoperative planning and technique.

The angled blade plate is suitable for bridging (wedge and multifragmentary supracondylar fracture components) or compression techniques. It can be used in combination with a varus malalignment correction to achieve better union rates.

Preoperative Planning

It includes defining the exact size and position of the plate. It is important to consider a variety of factors, including the patient’s anatomy, preoperative imaging, and the planned amount of correction.

It is also critical to ensure that the shaft of the angled blade plate aligns with the femoral axis and is not placed in an inappropriate position that will result in a valgus or varus osteotomy. To achieve this, a guide wire is inserted for orientation during surgery.

This technique enables a precise placement of the 130 degree angled blade plate during insertion, ensuring a stable fixation. It requires a high level of surgical discipline and skill.

Drilling

The 130 Degree Angle Blade Plate For Intertrochanteric is a high-quality, angled plate with dynamic compression holes that can be used for intertrochanteric fractures of the proximal femur. The plate is available with 4.5 mm screws for fixation.

The insertion of these devices requires a high level of surgical skill and strict adherence to a detailed preoperative plan. It is also important to ensure that the device is inserted exactly parallel to the guidewire in both planes.

In order to prepare the bone for insertion, three 4.5 mm holes are drilled in the lateral cortex of the femoral condyle. These need to penetrate about 1 cm. In young, harder bones, it may be necessary to drill the full depth of the chosen blade length.

The seating chisel is then hammered into the bone using a mallet. The chisel should be driven exactly parallel to the guidewire in both planes. The chisel should be “back-slapped” repeatedly with the slotted hammer to ensure that it remains in the correct position.

Guide Wires

A 130 Degree Angle Blade Plate For Intertrochanteric is a surgical option for the management of intertrochanteric fractures. These fractures are a common injury in young and elderly patients and result from high-energy traumatic events.

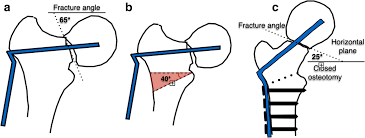

These fractures are often associated with varus malalignment, which is a risk factor for failure and nonunion of the fractures. A valgus intertrochanteric osteotomy can help correct this malalignment and improve healing rates of the fracture.

To achieve the desired correction, guide wires are placed around the joint to determine the insertion position of the plate. Once this is determined, the lateral aspect of the femoral shaft and the femoral head are imaged using a C-arm.

The insertion point is ideal when the blade plate lays over the patient’s skin in line with the guide wire. The angle between the femoral shaft and the blade plate is then used to determine the amount of correction.

Insertion

A 130 Degree Angle Blade Plate For Intertrochanteric is inserted to treat fractures of the intertrochanteric region, occasionally for subtrochanteric and femoral neck fractures. These angled plates have a U-cross-section that provides high strength with minimum bone displacement.

The insertion of these plates requires precise placement, and must be oriented in the frontal and sagittal planes for proper bone union. Misplacement may result in valgus, varus or rotational deformities.

During insertion, the shaft of the plate should be centered on the axis of the femur. To achieve this, the guide wires must be positioned 110 degrees from the shaft.

This lateral position of the guide wire allows for proper impaction on the fracture site to obtain compression across the fracture and achieve union (Figure 1C,D).

The screw trajectories shown in this end-on view demonstrate how the fully threaded 2.7 or 3.5 mm lag screws (shown with gliding hole), 6.5mm partially threaded lag screws or 4.0/4.5 mm cannulated, partially threaded lag screws compress the intercondylar split.